Call: 08045475134

Industrial Plate Heat Exchanger

Price 50000 INR/ Piece

MOQ : 1 Piece

Industrial Plate Heat Exchanger Specification

- Condition

- New

- Usage

- Industrial

- Structure

- Plate Heat Exchanger

- Voltage

- 415 Volt (v)

- Product Type

- Industrial Plate Heat Exchanger

- Color

- Blue

Industrial Plate Heat Exchanger Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4-5 Days

About Industrial Plate Heat Exchanger

We are engaged in supplying Industrial Plate Heat Exchanger that is widely acclaimed among our clients for its ruggedness and reliable performance. This is a premium quality tool capable of exchanging heat between two or more fluids. It is suitable to use for transferring heat between medium and low-pressure fluid. Due to its high build quality and robust design, we are seeing a huge demand for the Industrial Plate Heat Exchanger in the marketplace.

Advanced Heat Transfer Technology

This plate heat exchanger employs modern engineering to distribute heat quickly and effectively between fluids. Its robust plate structure ensures superior thermal performance, making it ideal for industrial tasks where precision and reliability are required. Clients benefit from reduced operational costs and optimized production workflows.

Reliable and Energy-Efficient Operation

Equipped with a 415 Volt power specification, this heat exchanger is built for consistent industrial use. The system is designed to minimize energy consumption while maximizing output, contributing to sustainability objectives and lowering energy bills for factories and process plants across India.

| Brand | Excellent Engineers Enterprises |

| Material | Stainless Steel |

| Warranty | 18 months |

| Phase | Three Phase |

| Power Source | Electric |

| Voltage | 415 V |

FAQ's of Industrial Plate Heat Exchanger:

Q: How is the Industrial Plate Heat Exchanger installed and used in industrial settings?

A: The heat exchanger is installed by connecting it to your plant's piping systems. It requires a 415 Volt electrical supply and can be integrated into existing process lines for heating or cooling fluids. Professional installation ensures optimal performance and safety.Q: What are the benefits of choosing a plate structure heat exchanger over other designs?

A: Plate heat exchangers are known for their high thermal efficiency, compact footprint, and ease of maintenance. Their modular plate arrangement promotes thorough heat transfer, reduces fouling, and simplifies cleaning compared to tubular models.Q: When is it appropriate to utilize this type of heat exchanger in industrial processes?

A: This heat exchanger is suitable for applications requiring efficient and rapid heat exchange, such as chemical manufacturing, food processing, and HVAC systems. It excels when space is limited and high operational reliability is necessary.Q: Where can I purchase and source the Industrial Plate Heat Exchanger in India?

A: You can obtain this plate heat exchanger directly from manufacturers and authorized suppliers located nationwide in India. Their sales and support teams can assist with product selection, delivery, and after-sales service.Q: What is the process for maintaining a plate heat exchanger for prolonged industrial use?

A: Routine maintenance involves checking for leaks, inspecting plate integrity, and cleaning the plates to prevent scaling. Scheduled service with recommended cleaning agents helps preserve performance and extends equipment life.Q: What are the primary usage scenarios for this heat exchanger?

A: It is used in industrial environments for heat recovery, fluid heating, and cooling processes. Common sectors include pharmaceuticals, food and beverage, oil and gas, and chemical industries.Q: How does the blue color of the equipment benefit industrial users?

A: The blue color provides high visibility for safety and quick identification on the shop floor, facilitating effective equipment management and helping workers spot the unit easily during routine checks or emergencies.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Heat Exchanger Category

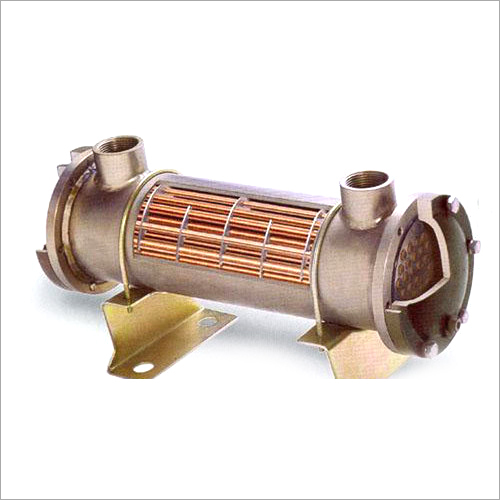

Industrial Tube Heat Exchanger

Price 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Condition : New

Structure : tube Heat Exchanger

Voltage : 380 Volt (v)

Carbon Steel Heat Exchanger

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Gray

Condition : New

Structure : tube Heat Exchanger

Voltage : 415 Volt (v)

Plate Heat Exchanger

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Gray & Blue

Condition : New

Structure : Plate Heat Exchanger

Voltage : 415 Volt (v)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese