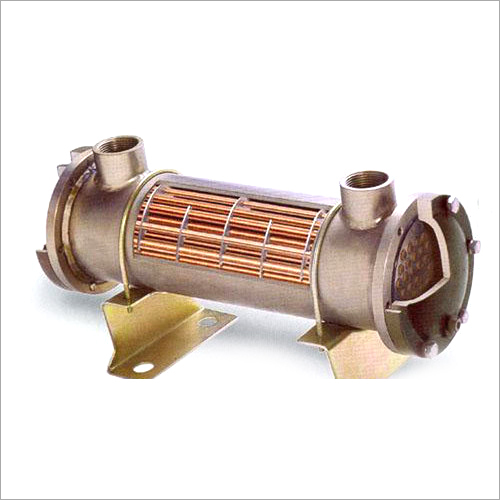

Carbon Steel Heat Exchanger

Price 50000.00 INR/ Piece

MOQ : 1 Piece

Carbon Steel Heat Exchanger Specification

- Temperature

- Medium-Temperature

- Condition

- New

- Usage

- Industrial

- Structure

- tube Heat Exchanger

- Size

- Standard

- Working Presssure

- 350 Bar

- Voltage

- 415 Volt (v)

- Product Type

- Carbon Steel Heat Exchanger

- Power

- 5000 Watt (w)

- Color

- Gray

Carbon Steel Heat Exchanger Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Available

- No

About Carbon Steel Heat Exchanger

Backed by a team of diligent professionals, we are actively engaged in supplying the first-rate Carbon Steel Heat Exchanger that is used to transfer heat between two or more fluids. It is used in the cooling and heating process. The offered device is made out of the first-rate alloyed metal with the help of cutting-edge tools and techniques. Therefore, it does not degrade due to extreme heat, impacts, rust, and other degrading factors.

Key Features and Benefits:

- Material: Constructed primarily from carbon steel, an alloy of iron and carbon, offering good strength and thermal conductivity.

- Heat Transfer: Utilizes the transfer of heat between fluids flowing through tubes and around them, without the fluids coming into contact.

- Durability and Strength: Handles high temperatures and pressures, making it suitable for demanding industrial applications.

- Cost-Effective: Generally more affordable than some other materials like stainless steel.

Engineered for Industrial Excellence

Crafted from high-quality carbon steel, this tube heat exchanger is designed specifically for industrial usage. Its resilient build and advanced design guarantee longevity and consistent performance, even in demanding environments. Compatible with a 415 Volt (v) power supply, it seamlessly integrates into existing systems, offering hassle-free operation.

Efficient Heat Transfer Technology

The tube structure maximizes the surface area for heat exchange, ensuring fast and effective temperature regulation. Its industrial-grade gray coating enhances durability, resisting wear and corrosion commonly found in heavy-duty settings. This combination of design and material ensures maximum thermal efficiency and reduced energy consumption.

| Body Material | Cast Iron |

| Frequency | 60 Hz |

| Maximum Working Pressure | 350 Bar |

| Phase | Three Phase |

| Power | 5 kW |

| Voltage | 415 V |

FAQ's of Carbon Steel Heat Exchanger:

Q: How does a carbon steel tube heat exchanger function in industrial applications?

A: A carbon steel tube heat exchanger works by transferring heat between two fluids without mixing them, using a set of tubes within a larger vessel. In industrial settings, it efficiently regulates temperatures during processes such as heating, cooling, or energy recovery.Q: What makes this heat exchanger suitable for industrial use?

A: This heat exchanger is constructed from robust carbon steel and engineered with a tube structure, providing durability and high thermal efficiency required for continuous industrial operate. Its 415 Volt compatibility ensures reliable performance in factory environments.Q: Where is this carbon steel heat exchanger manufactured and supplied from?

A: It is manufactured and supplied in India by experienced industry specialists, ensuring adherence to rigorous quality and safety standards.Q: When should this heat exchanger be installed in my facility?

A: The new carbon steel heat exchanger should be installed during equipment upgrades, new plant commissioning, or when an existing heat exchanger fails to maintain performance, especially where regulated heat transfer is vital.Q: What is the process for maintaining this tube heat exchanger?

A: Regular inspection and cleaning of the tubes are recommended to prevent fouling and scaling. Timely maintenance ensures consistent heat transfer efficiency and prolongs the device's operational lifespan.Q: How is the heat exchanger typically used in industrial settings?

A: Industrially, it is used for controlling process fluid temperatures, preheating feedwater, or condensing steam, depending on the specific application requirements of the manufacturing process.Q: What are the key benefits of using this carbon steel heat exchanger?

A: Key benefits include high durability, excellent heat transfer efficiency, resistance to corrosion, energy savings, and minimal maintenance needs, ideal for supporting demanding and continuous industrial operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Heat Exchanger Category

Industrial Tube Heat Exchanger

Price 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : tube Heat Exchanger

Voltage : 380 Volt (v)

Condition : New

Temperature : MediumTemperature Celsius (oC)

Industrial Plate Heat Exchanger

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Plate Heat Exchanger

Voltage : 415 Volt (v)

Condition : New

Temperature : MediumTemperature Celsius (oC)

Plate Heat Exchanger

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Plate Heat Exchanger

Voltage : 415 Volt (v)

Condition : New

Temperature : MediumTemperature

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese