à¤à¤®à¤¿à¤à¤¸ लà¥à¤à¥à¤®à¥à¤à¤¿à¤µ à¤à¤à¤à¤¨

Price 5000000 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

à¤à¤®à¤¿à¤à¤¸ लà¥à¤à¥à¤®à¥à¤à¤¿à¤µ à¤à¤à¤à¤¨ Specification

- पावर सोर्स

- Diesel Engine

- बिजली की आपूर्ति

- Diesel

- परिचालन तापमान

- सेल्सियस (oC)

- इनपुट

- Diesel Fuel

- चार्जिंग वोल्टेज

- वोल्ट (v)

- अवयव

- Cylinder Block, Pistons, Fuel Injection System

- आउटपुट

- Mechanical Power

- विशेषताएँ

- High Durability, Fuel Efficiency, Low Maintenance

- अंतरफलक

- Control Panel Display

- पावर रेटिंग

- IP65

- प्रॉडक्ट टाइप

- कमिंस लोकोमोटिव इंजन

- रेटेड वोल्टेज

- वोल्ट (V)

- आपूर्ति वोल्टेज

- वोल्ट (v)

- आयाम (एल* डब्ल्यू* एच)

- मिलीमीटर (mm)

- फंक्शन

- Heavy-duty power generation for locomotives

- वज़न

- 10000 किलोग्राम (kg)

- मौज़ूदा रेटिंग

- Depends on Load (typically 200-1000 A)

- फ़्रिक्वेंसी

- हर्ट्ज (एचजेड)

- Noise Level

- Compliant as per Railway Standards

- Cooling System

- Water Cooled

- Fuel Consumption

- Optimally Low at Rated Load

- Lubrication System

- Full-Flow Pressure Lubrication

- Starting System

- Electric Start

- Engine Type

- 4 Stroke, Turbocharged

- Mounting

- Base Frame Mounted

- No. of Cylinders

- 6, 12, 16 (Depending on Model)

- Max Torque

- Up to 16000 Nm @ 1800 RPM

- Emission Standard

- Complies with International Railway Emission Norms

à¤à¤®à¤¿à¤à¤¸ लà¥à¤à¥à¤®à¥à¤à¤¿à¤µ à¤à¤à¤à¤¨ Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- भुगतान की शर्तें

- , ,

- आपूर्ति की क्षमता

- प्रति दिन

- डिलीवरी का समय

- 20-30 दिन

- नमूना उपलब्ध

- No

About à¤à¤®à¤¿à¤à¤¸ लà¥à¤à¥à¤®à¥à¤à¤¿à¤µ à¤à¤à¤à¤¨

Cummins engines are widely used in locomotives for their reliability, efficiency, and low operating costs. They offer a range of power ratings from 49 to 4400 horsepower, with heavy-duty designs, high peak torque, and a high power-to-weight ratio. Cummins also provides advanced technology and low-maintenance diesel engines for locomotives, including models like the QSK19 and QSK50, along with power modules designed for easy installation and Tier 3 compliance for remanufacturing.

| Material | Mild Steel |

| Power | 800 Hp |

| Model Name/Number | Cummins |

| Weight | 10 Tons |

| Color | Black |

| Country of Origin | Made in India |

Advanced Engineering for Reliable Performance

Cummins Locomotive Engines incorporate cutting-edge technology, such as integrated sensors for temperature and oil pressure, ensuring continuous monitoring and operational safety. The combination of a turbocharged 4-stroke design and full-flow pressure lubrication extends engine life while maintaining impressive thermal conductivity, which optimizes heat dissipation even under the most demanding conditions.

Fuel Efficiency and Low Emissions

Each engine is engineered for optimal diesel consumption at rated loads, reducing overall fuel expenses. Compliant with international railway emission norms and noise standards, Cummins ensures environmentally responsible operation without compromising on horsepower and torque. This makes them suitable for railways focused on sustainability and regulatory compliance.

Flexible Configurations and Easy Maintenance

Whether your needs demand 6, 12, or 16 cylinders, Cummins offers engines tailored for a variety of locomotive models. The modular design, paired with base frame mounting, allows for straightforward installation and simplified maintenance routines, leading to reduced downtime and enhanced operational continuity across rail networks.

FAQ's of Cummins Locomotive Engines:

Q: How does the Cummins locomotive engine ensure reliable performance in diverse operating conditions?

A: Cummins locomotive engines are equipped with integrated temperature and oil pressure sensors, a robust water-cooled system, and a full-flow pressure lubrication system. These features allow the engine to operate efficiently and safely in temperatures ranging from -20C to 55C, ensuring dependable performance across varying environments.Q: What emission and noise standards do these engines comply with?

A: The engines adhere to international railway emission norms and are designed to meet railway-specific noise standards. This compliance guarantees environmentally-friendly power generation and minimal noise pollution during railway operations.Q: When is maintenance typically required for these locomotive engines?

A: Routine maintenance schedules depend on operational intensity but are generally minimized due to the engine's design for low maintenance. Regular checks of components like the fuel injection system, lubrication, and sensors are recommended, but the high durability and modular construction facilitate easier servicing and reduced downtime.Q: Where can these Cummins locomotive engines be installed?

A: These engines are suitable for installation in a wide range of locomotives, thanks to their base frame mounted configuration and flexible sizing. They are manufactured and supplied in India but are designed to accommodate international rail standards, making them adaptable across different railway infrastructures.Q: What is the process for monitoring engine performance during operation?

A: The engines feature a control panel display with analog or digital monitoring systems, allowing real-time observation of crucial data such as engine temperature, oil pressure, and running status. This ensures prompt detection of any anomalies for quick intervention.Q: How does the fuel efficiency of these engines benefit railway operators?

A: Optimally low fuel consumption at rated load reduces operating costs and enhances the overall efficiency of railway services. This results in significant long-term savings and lower environmental impact.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in रेल घटक Category

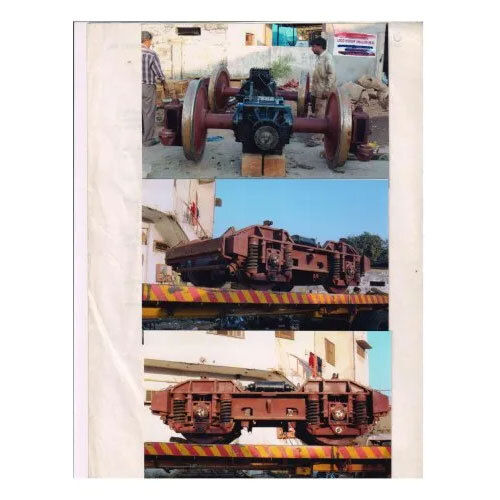

लोकोमोटिव स्पेयर पार्ट्स

माप की इकाई : टुकड़ा/टुकड़े

मटेरियल : Forged Steel

उपयोग : औद्योगिक

वारंटी : Yes

साइज : मानक

मूल्य की इकाई : टुकड़ा/टुकड़े

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese